High precision Ball Screw products are key elements in the heart of certain machines that are mainly incorporated in machine tools and semiconductor manufacturing equipment.

These Ball Screw element products are used to move slide an object in a straight line. To prevent the motion from slowing down due to the friction that occurs when sliding, all makers have developed high-performance Ball screw and linear motion bearing with various technologies.

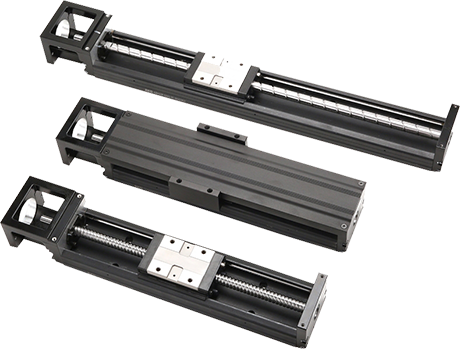

We VXO, a professional ball Screw manufacturer, has started from miniature ball screw manufacturing, and then developed more ball screw and linear motion devices like bearings, linear guideways and linear motion module with our original high rigidity mechanism and stable grinding technology.

We have gained a considerable share in China domestic Ball Screw and linear motion equipment market since then.

Ball screw accuracy grade refers to the level of precision and accuracy of the ball screw. The accuracy grade is usually expressed in terms of a number or a letter, such as C3, C5, or C7. The higher the number or letter, the higher the accuracy grade.

The accuracy grade of a ball screw is determined by the manufacturing process and the quality of the materials used.

The accuracy grade is important because it affects the performance of the ball screw in terms of positioning accuracy, repeatability, and smoothness of motion. Generally, ball screws with higher accuracy grades are more expensive but offer better performance. The appropriate accuracy grade for a given application depends on the required level of precision and the operating conditions of the ball screw.

Contact us now for more about the linear motion price!

Ground ball screw and rolled ball screw comparision

Ground ball screw and rolled ball screw comparision

Ball Screw Support Bearings

Ball Screw Support Bearings

Precision Cylindrical Roller Bearings

Precision Cylindrical Roller Bearings

Precision Deep Groove Ball Bearings

Precision Deep Groove Ball Bearings

Cylindrical Roller Bearings

Cylindrical Roller Bearings

Tapered Roller Bearings

Tapered Roller Bearings

Ball screw motor and linear motor comparison

Ball screw motor and linear motor comparison

Lead Screw Nut Material

Lead Screw Nut Material

Ball Screw Selection Guide

Ball Screw Selection Guide

How Does A Ball Screw Transmit Linear Movement?

How Does A Ball Screw Transmit Linear Movement?

Bidirectional Ball Screws: Paving the Way for Sustainable Manufacturing

Bidirectional Ball Screws: Paving the Way for Sustainable Manufacturing

How to select the right ball screw support bearing

How to select the right ball screw support bearing

Linear motion guides and bearings are unexpectedly used everywhere! The linear motion equipment ranges from relatively simple, such as an inexpensive seat actuator in a passenger vehicle, to a complex multi-axis coordinate system, complete with control and drive electronics for closed-loop positioning. No matter how simple or how complex the linear motion guide rails, at the most basic level they all have one thing in common. Moving a load through a linear distance in a specific amount of time, linear rails and linear actuators are used to control movements with different variables and complexity.

Let's look at some unexpected, yet common, examples of linear motion parts applications that most of us encounter every day. Linear motion guides and bearings can be found in many sectors.

Medical

The linear motion units are used in medical-technical platforms such as operating room beds, X-ray machines, MRI and CT Scanners as well as dentist chairs.

Buildings and Furniture

Linear motion devices can be seen in retail stores, yachts, hotels, museums and theaters, where linear motion control is required. We can also find linear motion products applied at home in our kitchens' worktops and our sliding doors or display cases. Linear motion guides and bearings are also used as safety barriers for elevators.

Aerospace

Linear motion equipment applications are everywhere in the aerospace industry. Aircraft seats, devices and equipment used in airports as well as extraction of slide-out components on aircrafts.

Packaging and Industrial

The need for linear motion parts can be required for positioning loads, palletizing, packaging, pick and place operations, filling operations and automated warehouses. You'll also need linear motion units at workstations such as cutting machines and painting machines.

In other words, anything that needs to go in a straight line is linear motion. Our experts at Technico speak to clients each day and meet their requirements to specification whether simple or complex. As a leading linear motion guide supplier, we assure our clients that their requirements are being met from the initial design, through prototyping and end product performance. Contact us today for more information about the linear motion price.

Being a kind of linear motion units, oil-free lubrication bearings are divided into solid inlaid bearings, composite bearings, oil-containing bearings, and new single lubricating materials according to the product structure.

The linear ball screw consists of a threaded metal shaft and a nut. When the motor drives the shaft to rotate, the nut moves along the shaft.

1. Model selection 2. Select the lead accuracy of the ball screw 3. Consider the support method of the ball screw.

Ball screw in good lubrication under the friction coefficient is very low. After all, this kind of linear motion parts is point contact, and long-term use of wear is also less. For CNC machine tools and such machines, requirements of high processing accuracy and the ability to maintain long-term stability of the linear motion equipment are necessary, and lower transmission resistance also laid the foundation for more high-speed transmission.