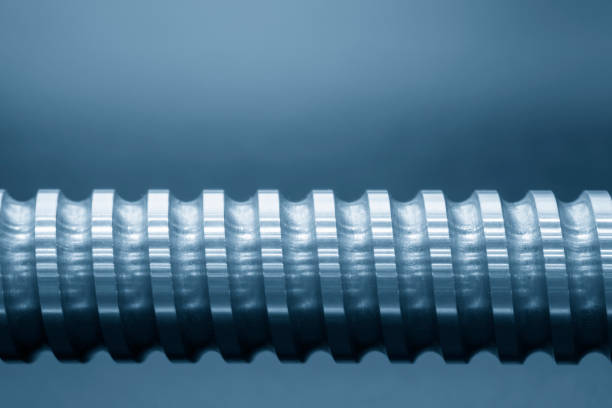

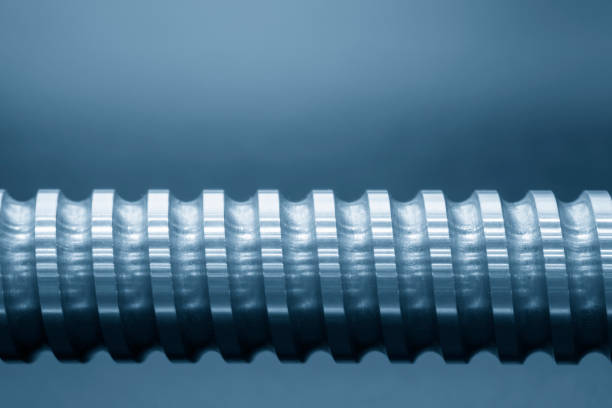

Ground ball screw and rolled ball screw comparision

Ground ball screw and rolled ball screw are two types of ball screws used in various industries. Let's compare them based on their properties and applications:

1. Manufacturing process: Ground ball screws are manufactured by grinding the screw threads and ball tracks to high precision, whereas rolled ball screws are made by cold rolling the threads and ball tracks.

2. Precision: Ground ball screws offer higher precision due to the grinding process, making them suitable for high-precision applications such as aerospace and medical equipment. Rolled ball screws have lower precision but are still suitable for many industrial applications.

3. Load capacity: Ground ball screws, as one of ball screw types, have a higher load capacity due to their higher precision and better surface finish, making them suitable for heavy-duty applications. Rolled ball screws have a lower load capacity but are still suitable for many industrial applications.

4. Cost: Ground ball screws are more expensive than rolled ball screws due to the higher precision and manufacturing process. Rolled ball screws are more cost-effective and widely used in various industries.

5. Maintenance: Ground ball screws require less maintenance due to their high precision and better surface finish. Rolled ball screws need occasional maintenance to ensure their performance.

In conclusion, ground ball screws are suitable for high-precision and heavy-duty applications, whereas rolled ball screws are widely used in various industrial applications due to their cost-effectiveness and versatility.

English

English