Sustainability has become a central focus in manufacturing, with industries worldwide seeking to reduce environmental impact while enhancing operational efficiency. In this quest for sustainability, bidirectional ball screws have emerged as valuable components, revolutionizing manufacturing processes. This blog explores how bidirectional ball screws are paving the way for sustainable manufacturing and the remarkable benefits they bring to the industry.

The Role of Bidirectional Ball Screws in Sustainability

Bidirectional ball screws are precision components that play a pivotal role in modern manufacturing. They enable precise control over linear motion, reducing waste, energy consumption, and environmental impact. These attributes make them an integral part of sustainable manufacturing practices.

Efficiency and Energy Savings

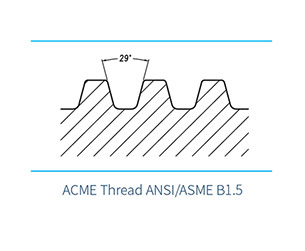

One of the key benefits of bidirectional ball screw is their efficiency. They convert rotary motion into linear motion with minimal friction, resulting in reduced energy consumption. This efficiency is essential for sustainable manufacturing, as it lowers operational costs and minimizes the environmental footprint of industrial processes.

Sustainable Materials and Coatings

Manufacturers are increasingly developing bidirectional ball screws using sustainable materials and coatings. For example, using lead-free materials and eco-friendly lubricants contributes to reducing the environmental impact of these components. Sustainable materials are not only more environmentally friendly but also exhibit excellent performance characteristics.

Extending Equipment Lifespan

Bidirectional ball screws are integral components in various industrial machines, including CNC equipment and robotic systems. By incorporating durable and efficient ball screws, manufacturers can extend the lifespan of their machinery. This reduces the need for frequent replacements, resulting in less waste and a smaller ecological footprint.

Precision and Reduced Material Waste

The precision offered by bidirectional ball screws significantly reduces material waste in manufacturing. Machines equipped with these components can perform intricate, accurate cuts and operations, minimizing errors that can lead to material waste. This precision is vital for sustainable manufacturing, as it reduces the need for additional resources and materials.

Bidirectional ball screws are leading the way for sustainable manufacturing practices. Their efficiency, energy savings, and precision contribute to reduced environmental impact, lower operational costs, and extended equipment lifespans. As industries continue to prioritize sustainability, bidirectional ball screws play a vital role in achieving these goals. They are not just components within machines; they are the foundation of sustainable manufacturing, paving the way for a greener and more efficient future in industry.

English

English