Ⅰ. Understanding of linear bearings

Metal linear bearings are low-cost produced linear motion systems for use with cylindrical shafts with infinite travel. Widely used in sliding parts of precision machine tools, textile machinery, food packaging machinery, printing machinery and other industrial machinery.

Linear bearing is a linear motion system with high precision, low cost and low frictional resistance. Linear bearings are used in combination with guide shafts, and use the rolling motion of balls to achieve infinite linear motion. Since the bearing ball is in point contact with the shaft, the operating load is small. Steel balls rotate with minimal frictional resistance, resulting in smooth motion with high precision.

Ⅱ. Working process of linear bearing

The linear bearing is equipped with a steel ball cage inside the outer ring, and the cage is equipped with multiple balls, and the balls move in an infinite cycle. The two ends of the cage are fixed by gasket retaining rings, and there is a notch window in the direction of the straight track where each steel ball is stressed. This part is to make the loaded steel ball and the shaft make rolling contact, with a very low friction coefficient Therefore, linear ball bearings are the most suitable bearings for mechanical equipment, automation equipment, and energy-saving equipment.

Ⅲ. Classification of linear bearings

1. Linear bearings are divided into shells according to materials: stainless steel, bearing steel, aluminum alloy (linear bearing with seat); cage: resin, stainless steel, bearing steel; surface treatment: chrome plating, nickel plating, surface anodic oxidation (linear bearing external fixation seat) and so on; the linear bearings included in our catalog are bearing steel shells, resin-lined cages, and products with no surface treatment; linear bearings with seats are the above ordinary linear bearings with aluminum alloy seats.

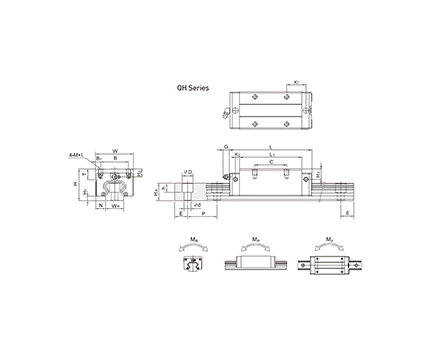

2. Linear bearings are divided into open type and closed type according to the shape; straight column type, single liner type (ordinary type), double liner type (extended type); single liner type with flange, double liner type with flange; double-sided cutting method Blue type, middle-cut flange type, four-sided cut flange type; heightened square type with fixing seat (the fixing seat is made of aluminum alloy, the surface is anodized), widened square type with fixing seat, etc.

3. Linear bearings are divided into two series by series, namely LM and LME series. LM series are used in Asia, Southeast Asian countries, Japan, Korea, China, etc. LME series are mostly used in Europe, the United States, Germany, Italy and other regions. The structural characteristics of the two series are roughly the same except for the different dimensions and aperture tolerances.

English

English