Introduction to trapezoidal threads

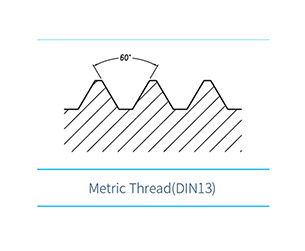

Trapezoidal threads are commonly used transmission threads that require high precision. They are used in applications such as the lead screws of lathes and the screw rods of medium and small sliders. There are two types of trapezoidal threads, with the national standard specifying a thread profile angle of 30 degrees and the British system using a profile angle of 29 degrees, which is less commonly used in China. Internal and external threads are difficult to loosen due to the tight fit of the taper. Compared to rectangular threads, transmission efficiency is slightly lower, but the manufacturing process is better, the root strength is higher, and they have good neutrality. If using split nuts, the clearance can also be adjusted. The trapezoidal thread is the most commonly used transmission thread.

Marking of trapezoidal threads

The marking of trapezoidal threads is composed of thread codes, tolerance band codes, and thread length codes. The trapezoidal thread code is represented by the letter "tr" followed by the nominal diameter multiplied by the thread pitch and rotation direction. The rotation direction of left-hand threads is marked as "lh", while right-hand threads are not marked. The tolerance band code for trapezoidal threads only indicates the medium diameter tolerance band, such as 7h and 7e, with uppercase letters for internal threads and lowercase letters for external threads. The thread length code for trapezoidal threads is divided into two groups, "n" and "l," where "n" represents medium thread length and "l" represents long thread length.

Threads are continuous convex parts with a specific cross-section that are processed on the surface of a cylindrical or conical parent body. Threads can be divided into cylindrical threads and conical threads based on their parental shape. They can also be classified into external threads and internal threads based on their position in the parent body. Depending on their cross-sectional shape (tooth shape), they can be classified as triangular threads, rectangular threads, trapezoidal threads, saw-tooth threads, and other non-standard threads.

Internal and external threads fit tightly against the taper, making them difficult to loosen. Compared to rectangular threads, transmission efficiency is slightly lower, but the manufacturing process is better, the root strength is higher, and they have good neutrality. If using opposite-opening nuts, the clearance can also be adjusted.

Applications of trapezoidal threads

High-speed steel trapezoidal thread cutting tools: High-speed steel trapezoidal thread cutting tools have sharp cutting edges, good toughness, and are not easy to collapse at the tip, making it possible to cut threads with higher precision and smaller surface roughness. They are commonly used for processing plastic materials, large-pitch threads, precision lead screw, and other workpieces, but their production efficiency is relatively low.

High-speed steel trapezoidal thread roughing tools: High-speed steel trapezoidal thread roughing tools feature a large relief angle to facilitate chip removal, with small angles on both sides for sufficient rigidity. They are suitable for roughing threaded rods with small pitch and trapezoidal threads. To facilitate left and right cutting and leave precision machining allowances, the tool width should be smaller than the groove bottom width W, and the included angle should be smaller than the tooth profile angle.

English

English