MIA0601-28-37-C5 is a ball screw with high precision and small-size characteristics. Below are the introductions to its basic parameters and suitable specific application scenarios:

MIA:Represents the product series code.

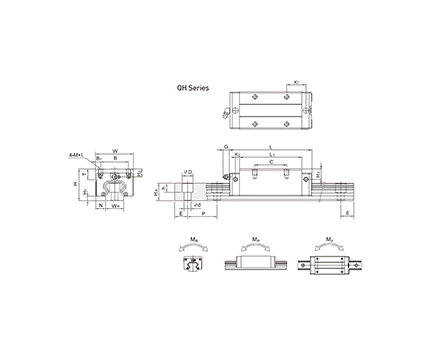

06: Refers to a nominal diameter of 6mm, i.e., the outer diameter of the ball screw. This size determines the basic load-bearing capacity of the ball screw. A 6mm diameter belongs to the micro-specification, suitable for compact installation spaces.

01: Represents a lead of 1mm, meaning that when the ball screw rotates one full circle, the nut moves 1mm along the axial direction. The small lead design enables precise micro-level displacement control.

28: Indicates an effective stroke of 28mm, which is the maximum linear movement distance that the nut can achieve and directly determines the movement range of the equipment's executive components.

37: Refers to the total length of the ball screw being 37mm, including the overall length of the non-threaded section and the threaded section. The selection should be based on the internal installation space of the equipment.

C5: Denotes an accuracy class of C5, which is a medium-high precision level. Its pitch error is usually controlled within 5μm, and it has high repeat positioning accuracy, meeting the needs of most precision transmission scenarios.

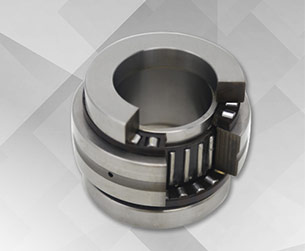

Material and Hardness: Mostly made of high-carbon chromium steel or alloy steel. After carburizing and quenching treatment, the surface hardness can reach HRC56-60, featuring good wear resistance and deformation resistance, thus extending the service life.

Load Capacity: The axial rated dynamic load is usually at the level of several hundred Newtons (specific data should refer to the manufacturer's specifications). It can bear the weight of the equipment's executive components and the working load, suitable for light to medium load scenarios.

Transmission Efficiency: The transmission efficiency of ball screws is generally over 90%, much higher than that of sliding screws. It can reduce power loss and improve the response speed of the equipment.

Friction and Temperature Rise: The rolling friction coefficient is small, resulting in low frictional heat during operation. The temperature remains stable under continuous working conditions, avoiding precision degradation caused by overheating.

II. Specific Application Scenarios

1. Small-Sized Precision Machining Equipment

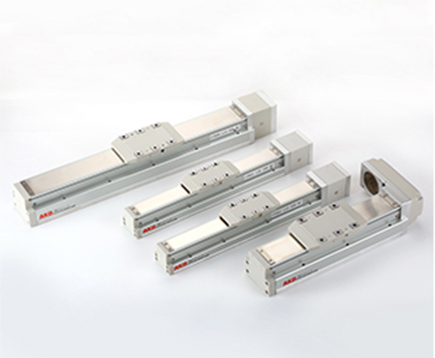

Micro CNC Engraving Machines:The C5-level accuracy ensures clear and uniform pattern processing on small workpieces such as metal and plastic. The 1mm lead can precisely control the engraving depth and path, and the 28mm effective stroke is suitable for the processing range of small workpieces.

Small Laser Cutting Machines:Used to drive the feed mechanism of the laser head. The small lead design enables fine adjustment of the cutting trajectory. The compact size with a total length of 37mm can be integrated into the narrow transmission space of the equipment, improving the cutting accuracy of micro-parts (such as electronic component pins and precision mold accessories).

2. Medical Diagnosis and Testing Equipment

Portable Testing Instruments:Such as micro biochemical detectors and immunoassays. The drive of their sample stages or detection probes can use this type of ball screw. The 1mm lead combined with C5 accuracy can achieve precise positioning of samples, and the total length of 37mm can be embedded into the compact structure of portable equipment, ensuring stable displacement during the testing process and reducing errors.

Minimally Invasive Surgery Auxiliary Equipment:In the executive end of some micro-surgical instruments (such as small biopsy sampling devices), this ball screw can achieve precise pushing over small distances. The low-friction characteristic can reduce the operating noise of the equipment and improve the stability of surgical operations.

3. Electronic and Semiconductor Equipment

Micro 3D Printers: For 3D printing of micro-parts such as jewelry and electronic components, the 28mmeffective stroke can meet the printing needs of small models. The stable transmission performance can avoid inter-layer offset in printing and improve the forming accuracy of micro-parts.

Semiconductor Packaging Equipment:Used to drive the micro-executive mechanism for chip handling or pin shaping. The C5-level accuracy can ensure precise alignment of semiconductor components, and the small-size design is suitable for the layout of dense transmission modules inside the packaging equipment.

4. Automated Sorting and Assembly Equipment

Micro-Part Sorting Machines:In the sorting lines of electronic components (such as resistors and capacitors) or precision hardware parts, this ball screw can drive the positioning mechanism of the sorting manipulator. Under frequent start-stop working conditions, the wear-resistant material can reduce the maintenance frequency. The advantage of 30% lower maintenance cost (compared with ordinary screws) can improve the cost-effectiveness of the equipment.

Micro Assembly Robots:Used in the fine-tuning mechanism of the robot's end effector to achieve precise assembly of small parts (such as watch gears and micro-motor rotors). The 1mm lead can control the assembly gap at the micro-level and improve the qualification rate of product assembly.

English

English