In the world of precision machinery, every component plays a crucial role in ensuring that operations run seamlessly. Custom roller bearings, in particular, stand out as essential components that provide tailored solutions for precision machinery. In this blog, we'll delve into the significance of custom roller bearings and how they are indispensable in achieving precision and performance in various industries.

The Versatility of Custom Roller Bearings

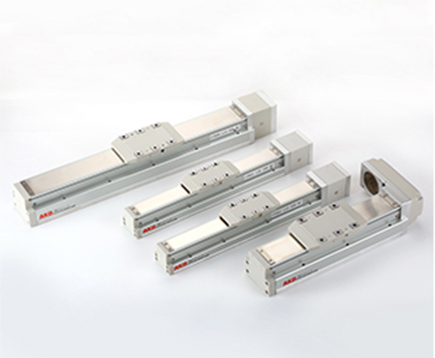

Custom roller bearings are highly versatile components that can be tailored to meet the unique needs of precision machinery. They are designed to handle a wide range of applications, making them a popular choice in industries such as aerospace, manufacturing, and automotive.

The Importance of Customization

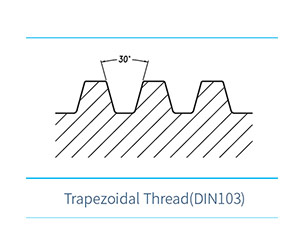

The customization aspect is where custom roller bearings truly shine. These bearings are engineered to cater to the specific requirements of individual machines and systems. They come in various configurations, including cylindrical, tapered, and needle rollers, each designed to handle different loads and conditions.

Meeting Unique Load Conditions

One of the primary advantages of custom roller bearings is their ability to address unique load conditions. Whether a machine requires high radial load capacity or exceptional thrust load support, custom roller bearings can be designed to meet these specific load requirements. This ensures that precision machinery can operate efficiently and reliably under the anticipated stresses.

Materials and Coatings for Durability

Custom roller bearings can be manufactured from a variety of materials that best suit the intended application. This may include stainless steel, ceramics, or specialized alloys that enhance resistance to corrosion, extreme temperatures, and abrasive conditions. Moreover, custom roller bearings can feature specialized coatings that further increase their durability, reducing the risk of premature failure.

Reducing Downtime and Extending Service Life

One of the key benefits of custom roller bearings is their role in reducing downtime and extending the service life of machinery. These bearings are designed to operate efficiently and reliably, resulting in longer service intervals and reduced maintenance requirements. In industries where operational continuity is paramount, the reliability offered by custom roller bearings can be a game-changer.

Custom roller bearings are the backbone of precision machinery, offering tailored solutions that ensure machines can operate at their best. Whether it's in aerospace, automotive manufacturing, or any other precision-driven industry, these bearings play a pivotal role in achieving the desired levels of precision and performance. The ability to customize roller bearings to specific load conditions, materials, and coatings, as well as their role in reducing downtime and extending service life, makes them indispensable in the world of precision machinery. It's not an exaggeration to say that custom roller bearings are the unsung heroes that quietly ensure that precision machinery operates seamlessly, day in and day out.

English

English