In the world of linear motion technology, recirculating ball screws have emerged as a powerful and efficient solution for converting rotational motion into smooth linear movement. These innovative devices play a crucial role in various industries, enhancing automation, precision, and productivity. In this blog, we will explore the advantages of recirculating ball screws and why they have become a preferred choice in modern engineering applications.

What are Recirculating Ball Screws?

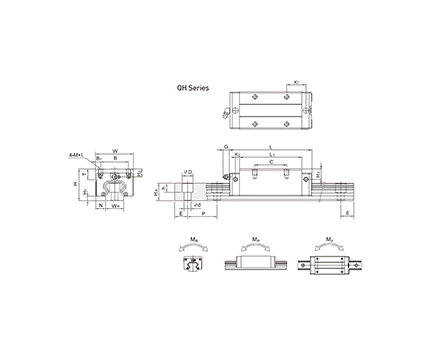

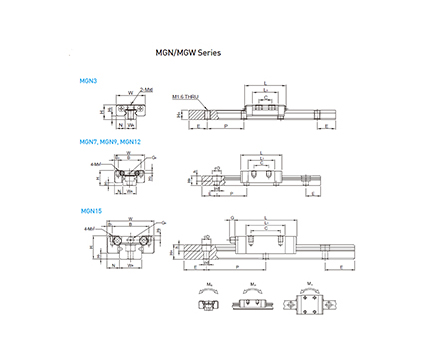

Before diving into ball screw advantages, let's understand what recirculating ball screws are. A recirculating ball screw consists of a threaded shaft (screw) and a nut with ball bearings inside. The ball bearings form a loop between the screw and the nut, allowing them to move smoothly against each other. When the shaft rotates, the ball bearings recirculate within the nut, translating rotational motion into linear motion.

Superior Efficiency and Low Friction

One of the primary advantages of recirculating ball screws is their exceptional efficiency. The rolling motion of the ball bearings minimizes friction compared to traditional sliding mechanisms. This reduced friction results in higher efficiency and lower power consumption, making them ideal for energy-efficient applications.

High Precision and Repeatability

Recirculating ball screws offer superior precision and repeatability in linear motion. The ball bearings ensure smooth and consistent movement, eliminating play and backlash. As a result, they are widely used in precision machining, robotics, and CNC machines, where accuracy is critical.

Improved Load Capacity

With their advanced design, recirculating ball screws can handle higher loads than other linear motion systems. The ball bearings distribute the load evenly, reducing stress on the system. This enhanced load capacity allows for the handling of heavy-duty applications without compromising performance.

Speed and Acceleration

Recirculating ball screws can achieve high speeds and acceleration rates, making them suitable for applications that require rapid and precise movement. Their smooth motion and reduced friction enable quicker response times and shorter cycle times, contributing to increased productivity.

Minimal Wear and Longevity

The recirculating roller screw assembly's design and material selection contribute to its durability, making it a cost-effective investment in the long run.

Backlash Elimination

Backlash, or the clearance between the screw and the nut, can cause inaccuracies and imprecisions in linear motion systems. Recirculating ball screws virtually eliminate backlash, providing a reliable and consistent motion profile, especially crucial in precision engineering and robotics.

Recirculating ball screws have revolutionized the world of linear motion with their efficiency, precision, and load-handling capabilities. These advantages make them indispensable in numerous applications, ranging from manufacturing and automation to aerospace and medical devices. By opting for recirculating ball screws, engineers and manufacturers can maximize efficiency, productivity, and overall system performance.

Whether it's CNC machining, 3D printing, or robotic automation, recirculating ball screws play a pivotal role in transforming rotational energy into precise linear movement, taking modern engineering to new heights of performance and innovation.

English

English