As the core component of precision transmission, the optimal performance of a ball screw is inseparable from the precise coordination and collaborative operation with key components such as support bearings, servo motors and linear guides. A successful transmission system is the perfect integration of mechanics, electronics and control.

Today, I will systematically explain the principles and methods for the coordinated operation of ball screws and their core components. My core philosophy is as follows: the coordination of a ball screw system is essentially about building a precision kinematic chain featuring clear force flow, rational constraints, and dynamic stability, with its core objective being to achieve efficient, accurate, and reliable transmission of power from the motor to the load.

I. What Is the Core of Ball Screw Coordinated Operation?

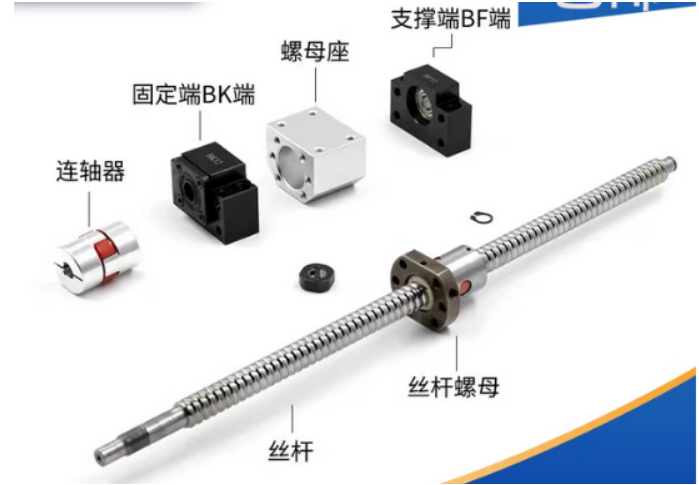

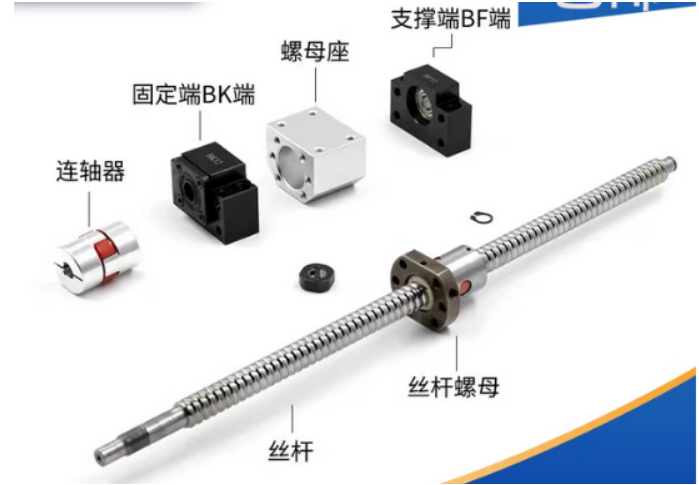

To put it plainly, the core of coordinated operation is to configure corresponding components for the ball screw according to its force-bearing characteristics (mainly withstanding axial forces), so as to rationally constrain its six degrees of freedom and achieve efficient power transmission. This includes: axial positioning, radial support, power input, linear guidance, and motion control.

When you need to design or maintain a complete linear motion system, understanding how each component works in coordination with the screw is the cornerstone of ensuring the performance and service life of the equipment.

II. How Do Core Components Cooperate with Ball Screws?

We need to build a "transmission galaxy" with ball screws at its core, and understand the role and connection method of each "planet".

1.Cooperation with Support Bearings: Establishing a Precise Rotational Foundation

Cooperation Method:

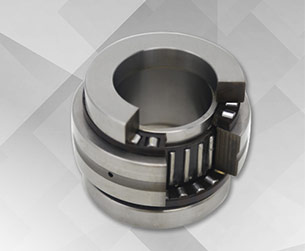

Fixed End (Drive Side): Use paired angular contact ball bearings with preload applied to withstand bidirectional axial and radial forces, achieving axial positioning of the ball screw.

Supported End (Non-drive Side):Use deep groove ball bearings or plain bearings to withstand radial forces only, while allowing the screw to expand and contract freely axially to compensate for thermal expansion.

2.Cooperation with Servo Motors: Injecting the Precision-driven Power Core

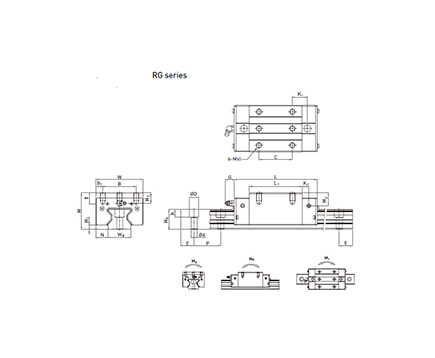

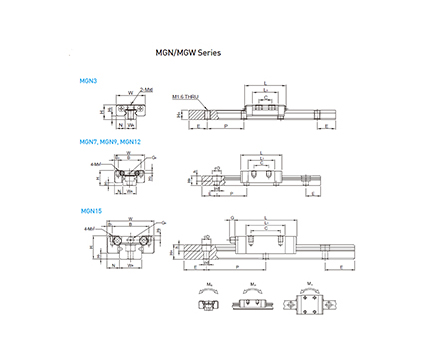

3.Cooperation with Linear Guides: Undertaking the Critical Task of Precision Guidance

4.Cooperation with CNC Systems: Endowing the System with an Intelligent Motion Control Brain

Cooperation Method: The controller issues position and speed commands.

The servo driver drives the motor to execute these commands with precision.

An encoder mounted on the motor end constitutes a semi-closed loop system; additionally, installing a linear scale on the worktable can form a fully closed loop system, which directly detects the load position and achieves the highest precision.

5.Practical Insights: The "Floating Connection" Principle

When connecting the nut flange to the worktable, there is one crucial technique to follow: never fully tighten the screws in one go! First, lightly fasten the screws to leave a small floating clearance, then run the worktable back and forth along the entire length of the guide rail several times. This allows the nut to self-align concentrically and eliminate installation stress. Finally, uniformly tighten the screws in a diagonal sequence. This is the key to ensuring smooth system operation free from excessive internal stress.

III. Common Problems in Coordinated Operation

1.Problem:Excessive noise is generated during ball screw operation. What matching issues could be the cause?

Answer: Troubleshoot in the following order:

① Poor coupling alignment (the most common cause).

② Excessive bearing preload or damaged bearings.

③ Misalignment between the guide rail and the ball screw, leading to nut binding.

④ Lubrication failure.

2.Problem: The worktable moves unsteadily with crawling phenomenon. How to resolve it?

Answer: This problem mostly stems from friction characteristics. Focus on checking the following aspects:

① Whether the guide rail sliders are properly lubricated.

② Whether the servo driver gain parameters are too low, especially the speed loop integral gain.

③ Whether there is additional friction caused by poor coupling between the ball screw and the guide rail.

3.Problem: How to select the appropriate ball screw accuracy class for my application?

Answer: Follow these principles:

A rule-of-thumb formula: Equipment target positioning accuracy ≈ Ball screw target travel tolerance (eₚ) × (1.5 ~ 2).

4.Problem: What special requirements are there for coordinated operation in vertical installation?

Answer: Safety is the top priority! The following components must be equipped:

① Servo motor brake as the primary safety line of defense.

② Mechanical anti-falling devices (e.g., backstops, safety nuts) as redundant backups.Meanwhile, the motor torque must be verified to ensure it can overcome the gravitational load.

Conclusion: Achieving the optimal coordinated operation of ball screws with various components is an integrated technology that combines mechanical design, precision measurement, and motion control. It requires engineers to adopt a systematic mindset—they should not only be capable of selecting individual components but also gain insight into the interactions between these components, ultimately building a high-performance transmission system that delivers synergistic effects greater than the sum of its parts.

English

English