Against the backdrop of the vigorous development of modern manufacturing, the continuous advancement of precision machining technology has undoubtedly injected strong impetus into its growth. In this process, ball screws, as a vital transmission component, are playing an increasingly prominent role. Not only do ball screws perform a core function in mechanical transmission systems, but they also demonstrate unparalleled advantages in enhancing machining accuracy and boosting work efficiency, thus becoming an indispensable part of driving industrial progress.

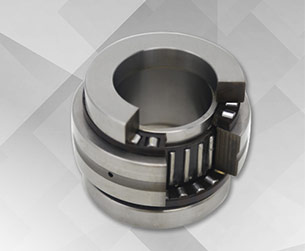

A ball screw is a precision transmission device composed of components such as a screw shaft, balls, and a ball nut. Its working principle relies on the rolling of balls between the screw shaft and the ball nut, enabling the conversion of rotary motion into linear motion. Compared with traditional conventional lead screws, ball screws feature a significantly lower friction coefficient, thus achieving highly efficient power transmission during the operation process.

In precision machining, accuracy is a critical metric for evaluating machining quality. Traditional machining methods are often subject to the impacts of factors such as friction and thermal expansion, which make it difficult to guarantee machining accuracy. However, thanks to its low-friction characteristic, the ball screw can effectively reduce machining errors. The manufacturing accuracy of ball screws is usually at the micron level, enabling them to maintain excellent stability even during high-speed and high-precision movements. By precisely controlling the movement of ball screws, high-precision machining requirements can be achieved, ensuring that the dimensions and shapes of products meet the design standards.

Efficiency has become one of the core goals that modern manufacturing strives to pursue. Given the increasingly stringent market requirements for product delivery cycles, traditional machining modes can hardly meet the urgent needs of rapid production. By virtue of its outstanding high-efficiency rotation performance, the ball screw can significantly accelerate machining speeds. In real-world application scenarios, equipment equipped with ball screws is often able to successfully complete more machining tasks in a shorter period of time, thereby driving a qualitative leap in production efficiency.

Precision machining has a wide range of applications, covering high-end industries such as aerospace, medical devices, and automotive manufacturing. Different industries have diverse requirements for machining equipment, and ball screws can meet the needs of various machining environments by virtue of their excellent adaptability. Even in some harsh working environments with high temperature, high humidity or heavy dust, ball screws can still maintain stable performance. With the advancement of technology, various types of ball screws have emerged on the market, such as dust-proof and high-temperature-resistant variants, which have further expanded their scope of application.

The low-friction characteristic of ball screws not only improves working efficiency but also reduces equipment wear. In traditional lead screw systems, wear and heat loss caused by friction often require regular maintenance and replacement. However, ball screws adopt rolling friction, which significantly reduces wear levels and thus extends their service life. This means that in long-term use, substantial maintenance costs and downtime can be saved, improving the overall economic benefits.

With the continuous advancement of technology, constant innovations are also being made to the design and materials of ball screws. New materials and manufacturing processes have been driving the steady improvement of ball screw performance, paving the way for their efficient and stable operation even under more extreme conditions in the future. The development of intelligent technologies will also bring new possibilities to the application of ball screws. By integrating sensors and control systems, the operational status of ball screws can be monitored in real time and adjusted automatically, thereby enhancing the level of automation and intelligence in precision machining.

The role of ball screws in precision machining is self-evident. They not only enhance machining accuracy and efficiency, but also feature excellent adaptability and low maintenance costs. With the continuous advancement of technology, the application fields of ball screws will become broader, and their importance in precision machining will be further strengthened. For the manufacturing industry, selecting suitable ball screws and giving full play to their advantages will become a crucial part of improving product quality and market competitiveness.

.jpg)

English

English

.jpg)