As we all know, in automated equipment, ball screws require the use of support units. The methods for using ball screws with screw support units are varied, and they are mainly determined based on specific application scenarios and requirements.

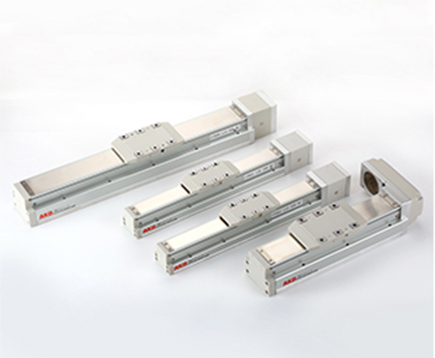

The standardized installation of screw support units is not difficult. You need to select a matching screw support unit model according to the model and specifications of the ball screw. Common support unit models include EK, EF, FK, FF, AK, AF, BK, BF, etc. These models feature standardized designs for the shaft ends and finished products of standard ball screw inventory items.

During the installation process, it is necessary to adjust the clearance between the ball screw nut and the worktable or support to ensure smooth movement of the ball screw. After installation, tools such as a dial indicator should be used to test the runout and axial clearance of the ball screw shaft end, ensuring that the installation accuracy meets the requirements.

After installation and testing are completed, careful commissioning is required. First, install the motor on the base, and connect the motor to the ball screw using a coupling. After the connection is completed, conduct sufficient commissioning tests, observe the operation of the ball screw, and check for phenomena such as abnormal noise, jamming, or instability. If any abnormalities occur, stop the machine promptly for inspection and adjustment.

Additionally, the maintenance and upkeep of ball screws and support units are also crucial, as they form the foundation for maintaining optimal operational performance. During use, you need to select an appropriate lubricant based on the operating environment and requirements, and lubricate the components according to the specified lubrication interval. To prevent external debris and moisture from entering the interior of the ball screw and support unit, sealing protection devices such as dust covers or telescopic sleeves should be used.

By taking measures such as correctly selecting and using the appropriate support unit model, properly adjusting clearances, ensuring installation accuracy, and performing regular maintenance and upkeep, the stable operation and long-term reliability of the ball screw system can be ensured.

English

English