What is a Ball Screw

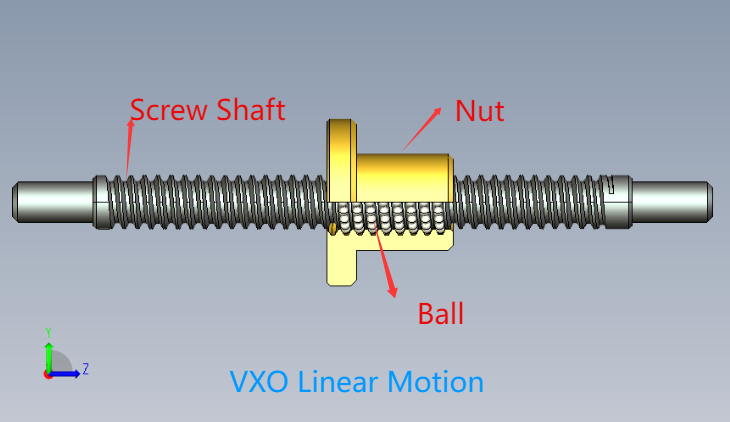

A ball screw is a precision transmission component that converts rotational motion into linear motion. Its core structure features steel balls embedded between the screw shaft and the nut, replacing traditional sliding friction with rolling friction. This design offers high transmission efficiency, excellent positioning accuracy, low wear, and long service life. Ball screws are widely used in CNC machines, automation equipment, and precision measuring instruments.

The History of Ball Screws

Before the invention of ball screws, converting rotary motion into linear motion relied on simple and inexpensive sliding lead screws, consisting of a screw and a nut. The first publicly documented ball screw design appeared in 1898 in The Practical Machinist magazine, developed by the Cleveland Machine Screw Company. However, the performance of this early design was limited, as inconsistent ball sizes often caused recirculation channels to clog. It wasn’t until after World War II, with advances in ball bearing manufacturing, that these issues were partially resolved.

By the 1950s and 1960s, ball screws began to be increasingly adopted in industrial machinery, especially in CNC machines and automation equipment. With improvements in manufacturing precision, companies in Japan and Europe developed high-precision, high-efficiency ball screws, enabling their widespread use in precision machinery and automation. Today, ball screws are essential components in modern manufacturing, valued for their high transmission efficiency, low friction, and long service life, widely used in CNC machines, precision measuring instruments, robotics, and aerospace applications.

Structure of a Ball Screw

For professionals in the industry, the structure of a ball screw is well understood. However, if you are new to the field or considering replacing a lead screw with a ball screw, take a close look at VXO’s structural components:

Screw Shaft

Structure: A shaft with precision helical grooves, typically with a circular arc cross-section (ball raceway).

Function: Serves as the rolling track for the balls, converting rotational motion into the linear motion of the nut.

Material: Usually made of high-carbon chromium steel (e.g., SUJ2) or stainless steel, heat-treated (quenched/ground) for hardness and wear resistance.

Ball Nut

Structure: Internally machined with helical grooves matching the screw shaft and equipped with a ball recirculation channel.

Function: Enables low-friction motion by rolling the balls between the screw and the nut.

Types:

Single Nut: simple, low cost, lower rigidity

Double Nut: preloaded, eliminates backlash, improves rigidity and precision

Balls

Material: High-carbon chromium steel or ceramic (for special applications)

Function: Roll between the screw and the nut, reducing sliding friction and improving transmission efficiency (up to 90% or higher)

Size Matching: Ball diameter must match the screw groove; tolerances are usually controlled at the micrometer level

Ball Recirculation System

Seals & Wipers

Function: Prevent dust, chips, and other contaminants from entering the nut, extending its service life

Common Forms: Rubber seals, metal wipers, etc.

Support Bearings

How to Choose a Ball Screw

Selecting the right ball screw is essential for ensuring the performance, efficiency, and longevity of your machinery. Key factors to consider include load capacity, speed and acceleration, ball nut configuration, precision, and environmental conditions. Understanding these requirements will help you choose a ball screw that meets your application needs and avoids issues like excessive wear or reduced accuracy.

Cost and performance are also important considerations. While high-precision ball screws may have a higher upfront cost, they offer better reliability, accuracy, and durability. By carefully evaluating your application requirements, you can select the most suitable ball screw and make an informed decision for long-term performance.

Choosing a Ball Screw Manufacturer

If you are looking to purchase a ball screw, you can consider sourcing from countries like Germany, China, or Japan. Each country has its own strengths:

German ball screws: known for precision and durability

Japanese ball screws: excel in high-speed and high-accuracy applications

Chinese ball screws: cost-effective solutions with flexible customization options

Choosing the right supplier depends on your specific requirements and budget. Partnering with a reliable China ball screw manufacturer can provide high-quality ball screws for CNC machines, linear motion systems, and automation equipment, offering low backlash, high efficiency, and long service life.

English

English