A lead screw is a transmission pair component that converts rotational motion into linear motion. On machine tools, it is a crucial part used to achieve feed motion. Machine tool lead screws must not only accurately transmit motion but also transfer a certain amount of power. Therefore, they have specific requirements for precision, strength, and wear resistance.

As a high-precision component,the primary lead screw function is to precisely determine the coordinate position of the worktable and convert rotational motion into linear motion while transmitting a certain level of power. Consequently, it has strict requirements for precision, strength, wear resistance, and other performance indicators. For this reason, every process of lead screw machining—from blank to finished product—must be carefully considered to improve its machining accuracy.

1. Classification of Lead Screws

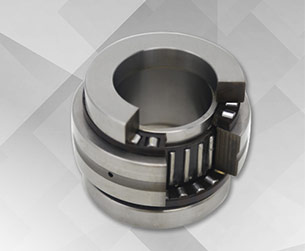

Machine tool lead screws can be categorized into three types based on their frictional characteristics: sliding lead screws, rolling lead screws, and hydrostatic lead screws. The choice of lead screw material is critical here, as it must resist wear while maintaining dimensional stability. Due to their simple structure and ease of manufacturing, sliding lead screws are widely used in machine tools.

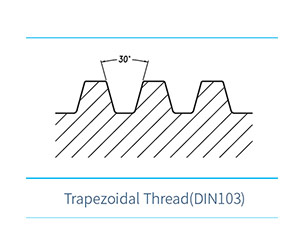

The thread profile of sliding lead screws is mostly trapezoidal. Compared with triangular threads, this profile offers advantages such as higher efficiency, better transmission performance, higher precision, and easier machining.

Rolling lead screws are further divided into two main categories: ball screws and roller screws. Compared with roller screws, ball screws feature lower friction, higher transmission efficiency, and superior precision, making them more commonly used. However, their manufacturing process is relatively complex.

Hydrostatic lead screws boast numerous advantages and are often employed in the feed mechanisms of precision machine tools and CNC machine tools. Their thread profile is identical to that of standard trapezoidal threads, but the profile height is 1.5 to 2 times that of standard threads of the same specification. This design aims to achieve effective oil sealing and enhance load-bearing capacity. Nevertheless, hydrostatic lead screws require cumbersome adjustments, a dedicated hydraulic system, complex manufacturing processes, and result in higher costs.

A lead screw is a slender and flexible shaft with a large ratio of length (L) to diameter (d), typically ranging from 20 to 50, resulting in poor rigidity. Its complex structural shape—featuring high requirements for thread surfaces, as well as steps and grooves—makes it prone to deformation during machining.

In the national standard GB785-65, the precision of ordinary trapezoidal threads is classified based on pitch diameter tolerances. There are five basic parameters: outer diameter (d), inner diameter (d₁), pitch diameter (d₂), pitch (t), and thread half-angle (α/2). To ensure accurate motion transmission, the precision of lead screws and pitches is divided into 6 grades (4, 5, 6, 7, 8, 9) according to JB2886-81, with precision decreasing sequentially from grade 4 to grade 9.

The application scope of each precision grade is as follows:

Grade 4: The highest precision grade currently available, rarely used in general applications.

Grade 5: Used in precision instruments and high-precision machine tools, such as coordinate boring machines and thread grinding machines.

Grade 6: Applied to precision instruments, precision machine tools, and CNC machine tools.

Grade 7: Suitable for precision thread lathes, gear-cutting machines, and CNC machine tools.

Grade 8: Used in general-purpose machine tools, such as horizontal lathes and milling machines.

Grade 9: Employed in shapers, drilling machines, and feed mechanisms of general machine tools.

Precision lead screws generally refer to grades 5, 6, and 7. They are categorized into two types: hardened precision lead screws and non-hardened precision lead screws. The former offers superior wear resistance and can maintain machining accuracy for extended periods but requires complex manufacturing processes, including high-precision thread grinding machines and specialized heat treatment equipment. In contrast, the latter only requires precision lead screw lathes.

The technical requirements for lead screws can be divided into the following items:

① Precision grade;② Surface roughness;③ Single pitch tolerance and cumulative tolerance over a specified length;④ Pitch diameter roundness tolerance;⑤ Outer diameter equality tolerance;⑥ Outer diameter runout tolerance;⑦ Thread half-angle tolerance;⑧ Tolerances for pitch diameter, outer diameter, and inner diameter.

English

English