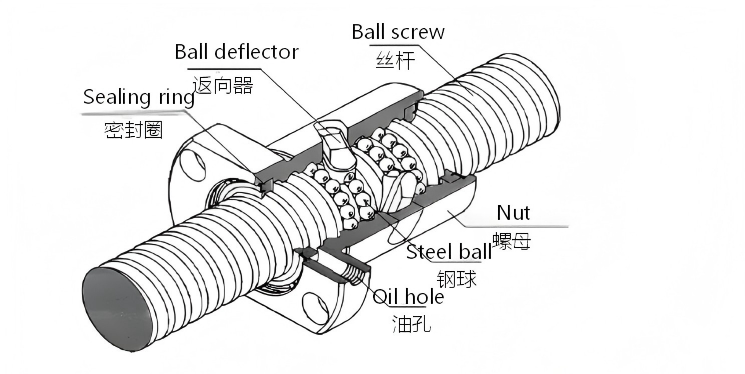

In the realm of ball screw transmission, preloading the ball screw nut is the "precision craft" that eliminates transmission backlash and boosts system rigidity. A perfectly calibrated preload force enables your equipment to respond with seamless precision and robust performance; conversely, an improper preload will become the root cause of excessive wear, sharp temperature rises and even premature failure. I have always believed that the art of preloading lies in striking the delicate balance between rigidity and service life with pinpoint accuracy. Below are the three mainstream preloading methods to achieve this goal, each being a sophisticated solution tailored to distinct application scenarios.

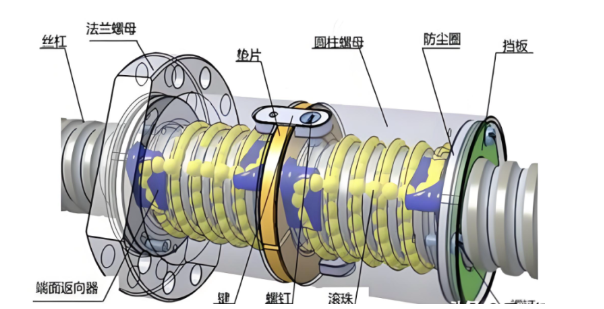

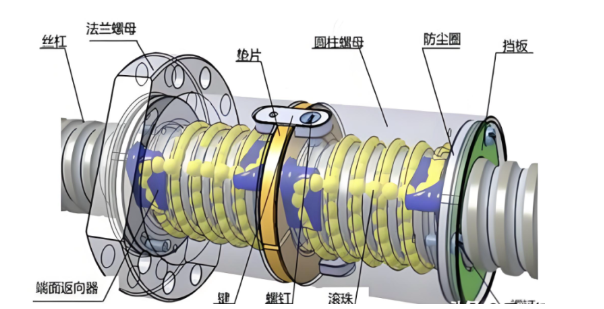

I. Double-Nut Shim Preloading: A Classic, Reliable "Rigid Foundation"

This is the most traditional, stable and widely used preloading method, and it can be called the cornerstone of stability in the field of preloading.

Working Principle

Two independent nuts are separated by a precision shim. During assembly, a force is applied via locking bolts, exerting a forward force on one nut and a reverse force on the other, thereby creating a preload within the internal ball train.

Core Advantages

Ultra-high rigidity: The robust structure can withstand extremely high bidirectional axial loads.

Precise control and adjustment of preload force: An extremely accurate preload force setting can be achieved by grinding the thickness of the shim.

High reliability and long service life.

Applicable Scenarios

Heavy-duty CNC machine tools, high-precision machining centers, and any application with stringent requirements for rigidity and precision. This is my most recommended all-purpose solution.

II. Double-Nut Threaded Preloading: A Flexible, Adjustable "Field Essential"

This method offers immense convenience for on-site adjustment of preload force.

Working Principle

Internal and external threads are machined on the two nuts. By rotating one of the nuts (the adjusting nut), the relative position between the two nuts is altered to apply a preload force, which is then locked in place with a lock nut.

Core Advantage

Adjustable preload force: Preload can be adjusted on-site without disassembly, making it extremely convenient.

Practical Warnings

Slightly lower rigidity: Under extreme heavy loads, minor deformation of the threaded connection may result in slightly lower rigidity compared to the shim type.

Locking is critical: It is imperative to ensure the absolutely reliable anti-loosening measures for the lock nut; otherwise, loosening may occur during operation, leading to preload failure.

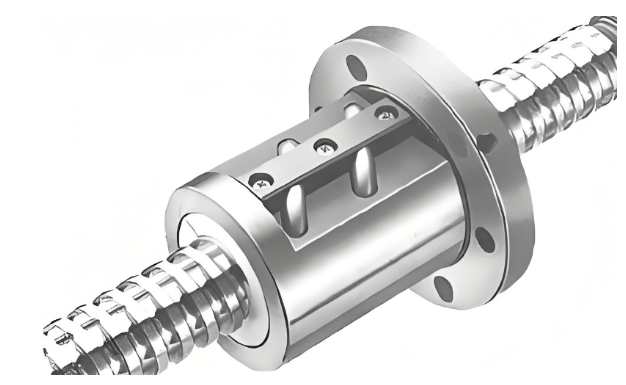

III. Offset Pitch Preloading: A Compact, Integrated "One-Piece Solution"

This is a more sophisticated design that integrates the preloading function into a single nut.

Working Principle

Two sections of internal threads with slightly different pitch values are machined on both ends of a single nut body. As the steel balls recirculate from one end to the other, the abrupt change in pitch forces the balls to be compressed in the load zone, thereby generating a preload force automatically.

Core Advantages

Compact structure with a small axial dimension

No adjustment required: The preload force is predetermined during manufacturing, enabling effortless operation.

Applicable Scenarios

Applications with strict structural size constraints and a demand for lightweight design, such as semiconductor equipment and precision instruments.

Conclusion: Preloading a ball screw nut is a precise calibration of the balance between rigidity, precision, service life and cost. The double-nut shim type stands as the gold standard for uncompromising performance; the double-nut threaded type delivers flexible adjustability; and the offset pitch type caters to the demands of highly integrated designs.

May this preloading guide serve as a precision torque wrench in your hands, helping you infuse every transmission system with the perfect amount of vital preload. Let us join hands and start from the core of preloading to lay a solid foundation for the exceptional performance of your equipment!

English

English