Three Processing Methods of Ball Screws

Currently, three rough machining methods are commonly used for ball screws in China: whirling milling, grinding with abrasive wheels, and hard turning. The characteristics of these processing methods are compared as follows.

I. Abrasive Grinding Process

Abrasive grinding is a traditional rough machining method and is also widely adopted at present. Ordinary lead screw grinders (or special grooving grinders) are commonly used to grind 90-degree V-shaped grooves on workpieces. Although this method is reliable, its low production efficiency can no longer meet current production needs. To improve efficiency, some users have adopted the deep-cut slow-feed grinding process on lead screw grinders. For conventional rough grinding, the single feed depth is 0.05-0.10mm with a headstock speed of 10-20r/min; while for deep-cut slow-feed grinding, the single cutting depth reaches 2-3mm with a headstock speed of 1-2r/min. This process is suitable for the rough machining of lead screws of various diameters and lengths, but it has the following disadvantages:

1.Due to the excessive single feed depth, a large amount of heat generated at the grinding area cannot be cooled in time, leading to raceway annealing, a significant decrease in hardness, and the occurrence of microcracks, which seriously impairs the quality of ball screws.

2.Low production efficiency.

3.Grinding requires cooling, which generates a large amount of oil fume and pollutes the working environment.

4.After grooving, the ball screws still require semi-finish grinding and finish grinding.

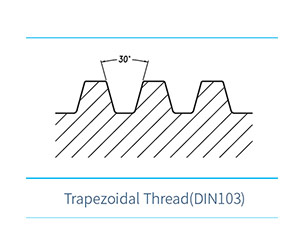

II. Hard Turning Process

With the development of CBN tool technology, the hard turning process is now widely applied in the rough machining of ball screws. The optimal cutting speed for CBN tools is 100-300 meters per minute. During turning, the single cutting depth is 0.15-0.20mm, and the workpiece speed is relatively high to maximize the advantages of CBN tools. For example, when turning a lead screw with a diameter of 40mm and a pitch of 6mm, the workpiece speed is approximately 680r/min. The characteristics of this process are as follows:

1.Compared with the deep-cut slow-feed grinding process, its production efficiency is increased by about 5-10 times.

2.Only 90-degree V-shaped grooves can be machined on the workpiece. When the pitch is large, the axial cutting force becomes significant, making it unsuitable for processing workpieces with large pitches. Generally, it is used for workpieces with a pitch of 6mm or less.

3.Due to the high workpiece speed and large cutting resistance during hard turning, slender parts are prone to vibration and bending deformation, making them impossible to process. Therefore, the hard turning method is suitable for workpieces with a pitch of 6mm or less, a length of 1m or less, and a small length-to-diameter ratio.

4.The price of inserts is low.

5.After grooving, the lead screw still requires semi-finish grinding and finish grinding.

III. Hard Whirling

Hard whirling technology has been relatively mature in research and application overseas. In recent years, China has conducted in-depth research on hard whirling technology and achieved significant progress. The whirling tool is a CBN formed tool, which is designed to match the arc of the ball screw raceway, enabling semi-finish grinding accuracy in a single cutting pass. Basically, all hard whirling tools have been localized in China, and the tool price has dropped to a reasonable level, resulting in a substantial reduction in production costs. For the hard whirling process of ball screws, the single cutting depth can reach the full tooth depth, and the headstock speed ranges from 1 to 6r/min depending on the workpiece diameter. The characteristics of hard whirling are as follows:

1.The thread raceway can be milled and formed in one pass, allowing the workpiece to proceed directly to finish grinding and eliminating the semi-finish grinding process.

2.The workpiece rotates at a relatively low speed, and the milling cutter head is equipped with multiple milling cutters that operate at a speed of 180-240m/min, achieving higher production efficiency than the hard turning process. In contrast to turning, where only one tool is involved in cutting, whirling can involve up to 12 tools simultaneously. This significantly reduces the cutting force borne by each tool and avoids problems such as workpiece vibration and bending deformation.

3.More than 90% of the cutting heat generated during whirling is instantly carried away by the chips. As a result, the cutting heat is not transferred to the ball screw, preventing phenomena such as burning and annealing of the ball screw raceway that may occur during grinding.

4.No cooling is required during whirling, eliminating oil fume pollution in the working environment.

5.A single sharpening of the milling cutter can achieve a cutting spiral length of approximately 500 meters (equivalent to machining 8-10 lead screws with a thread length of 3000mm and a pitch of 10mm).

6.Although the price of whirling cutters is higher than that of turning tools and the regrinding of inserts is complex, tool manufacturers can provide insert regrinding services.

Hard whirling is particularly suitable for the semi-finishing of long lead screws and those with a large length-to-diameter ratio.

Each of the three ball screw machining methods has its own advantages and disadvantages. We can select the optimal one based on specific requirements.

English

English