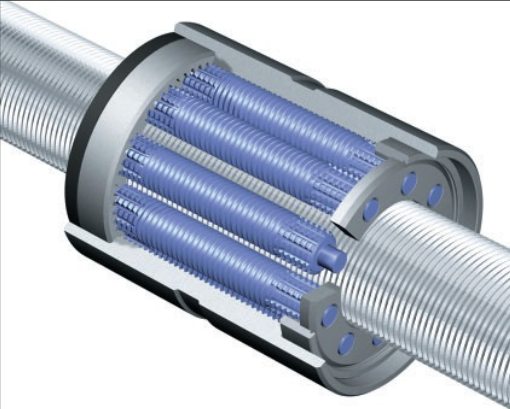

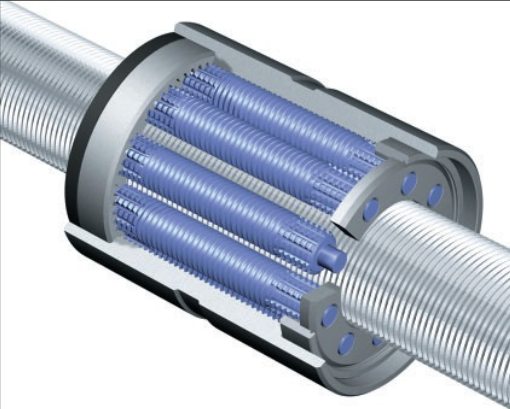

What exactly makes planetary roller screws "stand out"? Compared with traditional linear actuators such as gear racks, hydraulic servos, and ball screws, they demonstrate comprehensive advantages in performance.

In terms of load-carrying capacity,they have a larger contact area under the same volume. Their static load capacity is 3 times that of ball screws, and their service life is even extended to 15 times, which can meet the demand for long-term high-load operation of humanoid robot joints.

In terms of speed,their maximum linear speed can reach 2000mm/s, and the input rotational speed exceeds 5000rpm, enabling robots to move more agilely.

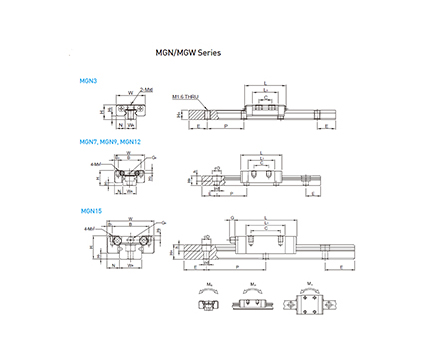

In terms of volume,due to the flexible pitch design, their volume is 2/3 smaller than that of ball screws under the same load-carrying capacity, perfectly adapting to the miniaturized joint design of humanoid robots.

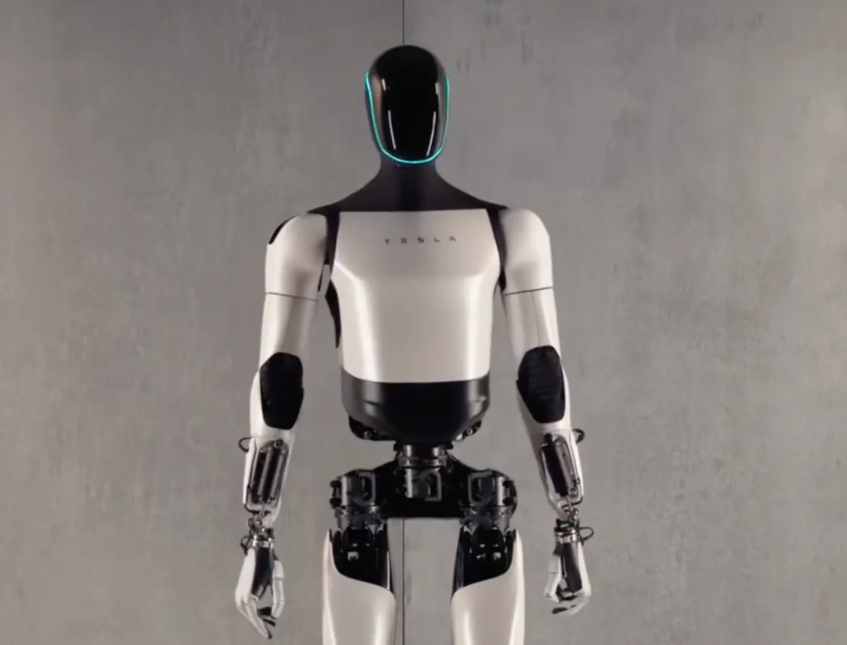

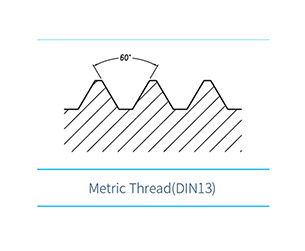

In addition, they also have the advantages of high precision and low noise. The non-circular thread with a small lead angle of the screw shaft can achieve precise micro-feeding, while the synchronous circular motion of the rollers and the main screw greatly reduces vibration and noise.These characteristics make them the "only choice" for linear joints of advanced humanoid robots such as Tesla Optimus.

From the perspective of application scenarios, planetary roller screws have long broken through the limitations of a single field and been widely applied in the automotive industry, construction machinery, machine tool equipment, medical devices, and other fields.

In the automotive sector, they can be used in hydrostatic clutch actuators and mechatronic braking systems, replacing traditional hydraulic drives to improve response speed and electronic control levels.

In the oil and gas industry, their electric cylinders can replace some pumping units, enabling cleaner and more environmentally friendly oil transportation.

In the field of machine tool equipment, they are gradually replacing ball screws, leveraging their advantages of high precision and long service life to enhance machining accuracy.

However, the global market size of planetary roller screws was only 1.27 billion US dollars in 2022. With the boom in the humanoid robot industry, this market is about to experience a "magnitude leap".

The mass production plans for humanoid robots are injecting strong momentum into the planetary roller screw market. Tesla has revealed that its Optimus humanoid robot will enter mass production with 5,000 units in 2025, expand production to 50,000 units in 2026, and is expected to achieve an annual output of 500,000 to 1 million units by 2029. Figure AI has also launched automated production lines, aiming to increase its annual production capacity to 100,000 units within 4 years.

From the perspective of structural disassembly, a single humanoid robot has a significant demand for planetary roller screws. Taking Optimus as an example, it is equipped with 14 linear joints, each requiring one planetary roller screw, and the drive system of its dexterous hands also relies on micro-sized screws.

In terms of value share, planetary roller screws account for 19% of the mechanical components in humanoid robots, making them the core component with the highest value proportion. According to calculations, if the global output of humanoid robots reaches 1 million units in 2029, with each unit equipped with 14 planetary roller screws and a unit price of 800 yuan, the incremental market size of this component in that year will reach 11.2 billion yuan—representing a several-fold growth compared to the global market size in 2022.

As humanoid robots move from laboratories to commercialization, the planetary roller screw market is set to open a "100-billion-level" growth channel. After breaking through barriers in materials, processes, and equipment, domestic enterprises are transforming from "substitutors" to "leaders". This will not only drive cost reduction and efficiency improvement in the humanoid robot industry, but also help China seize the global competitive high ground in the field of high-end precision manufacturing, injecting new momentum into the upgrading of the manufacturing industry.

English

English